The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Dozens of kilometers off the coast, in the deep blue sea, rows of pristine white windmills stand silently. Like elegant giants, they wave their nearly 100-meter-long arms, transforming the raging sea winds into the currents of civilization.

If you zoom in, passing through the heavy steel towers and entering the cabin—about the size of a studio apartment—you'll see the "heart" of this behemoth—the main shaft bearing.

It is the soul of the wind turbine, and also the loneliest guardian of industry. It has a 20- to 25-year contract with humanity: once installed, it must maintain near-perfect operation amidst the corrosive effects of salt spray and relentless rotation, day and night, until its final moments.

Today, let's talk about how this "steel heart" completed this two-decade-long "extreme survival challenge" in such extreme conditions.

I. The Lonely Guardian: What Hellish Mode Did It Face?

If ordinary car bearings are like teenagers strolling in a city park, then offshore wind turbine bearings are like lone heroes in the polar regions.

"Titan-level" pressure: The blade sweep area of modern offshore wind turbines often exceeds three football fields. When strong sea winds blow, the enormous thrust generated by the blades is concentrated on the main shaft bearing. Imagine thousands of tons of load repeatedly compressing those steel balls or rollers, each three or four meters in diameter; this pressure is enough to deform ordinary metal instantly like putty.

The "slow poison" of salt spray: The ocean is beautiful, but deadly to metal. High humidity and high salinity air are extremely corrosive. Even the slightest crack allows salt spray to seep in, gnawing at the smooth, mirror-like surface of the bearing like poisonous insects. Once a tiny rust spot forms, it quickly evolves into fatal flaking during high-speed rotation.

The Cost of Repairing a Wind Turbine Bearing at Sea: On land, a broken part might only require a crane; but at sea, replacing a main shaft bearing means deploying an expensive deep-sea crane vessel and waiting for a rare "construction window" (calm weather). The cost of replacing a major component at sea often reaches millions or even tens of millions of RMB.

Therefore, wind turbine bearings must achieve one thing: they must not "break down" within 20 years.

II. Alchemy and Micrometer-Level Romance: How to Create an "Indestructible Body"?

To fulfill this 20-year contract, engineers have poured almost artistic craftsmanship into the bearings.

1. The Battle for Steel "Purity"

Bearing fatigue often begins with tiny internal impurities. To manufacture wind turbine bearings, steel mills need to use the purest steelmaking processes. Engineers use vacuum degassing technology to reduce the oxygen, hydrogen, and nitrogen content in the molten steel to the limit. Under a microscope, this steel is as crystal clear as a glacier, without any pinholes. Even a single micron-sized impurity, after 20 years of repeated crushing, can become the trigger that destroys the entire bearing.

2. High-Tech Coating: Steel's "Bulletproof Vest"

To combat salt spray, bearing surfaces are often coated with a special "bulletproof vest." This could be a process called black oxidation, or a more advanced anti-corrosion coating. It not only blocks moisture but also provides extra protection during extreme friction. This thin film is the last line of defense between steel and the sea.

3. Lubricating "Blood Circulation"

The lubricating grease inside the bearing is its blood. In a wind turbine, an intelligent lubrication system acts like a precision surgical pump, delivering fresh blood to every stress point on a timed and measured basis. This grease must not only withstand high temperatures but also maintain fluidity at sub-zero temperatures in winter, ensuring that every ball bearing is "skating" rather than "wearing."

III. A Smart "Stethoscope": It's No Longer Silent Steel

In the past, engineers could only pray that the bearings wouldn't break. Today, we've equipped bearings with a "brain" and "nerves."

Densely packed vibration sensors and temperature probes are distributed across the bearing races. This data is transmitted in real-time via satellite to a monitoring center thousands of miles away.

It's like giving this guardian a 24/7 personal physician.

If the bearing emits even the slightest unusual "groan" (abnormal vibration frequency), the AI algorithm will immediately detect it.

It can accurately predict that the bearing may experience fatigue after 3,000 hours.

Therefore, the maintenance team can bring lubricant or small parts for "maintenance" on the next sunny day, instead of waiting until it's completely broken down before attempting "rescue."

This shift from "passive maintenance" to "predictive maintenance" represents the highest level of human control over machinery.

IV. Two Decades of Trials and Tribulations: This is Not Just Technology, But a Commitment

When we talk about "green energy" and "carbon neutrality," we often think of grand narratives. But what truly supports these visions are these bearings, silently rotating hundreds of meters in the air, in the pitch-black night, and amidst raging storms.

They have witnessed the sunrise and sunset over the sea, endured the baptism of typhoons, and suffered twenty years of solitude.

When the twenty-year contract expires, and the wind turbine completes its mission and is dismantled, if we open the main shaft bearing and find it still gleaming with a cold, metallic sheen, still able to rotate smoothly, that is the most romantic reply from industrial civilization to nature.

A salute to these guardians hundreds of meters in the air. Because of their "rotation," we have our "light."

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

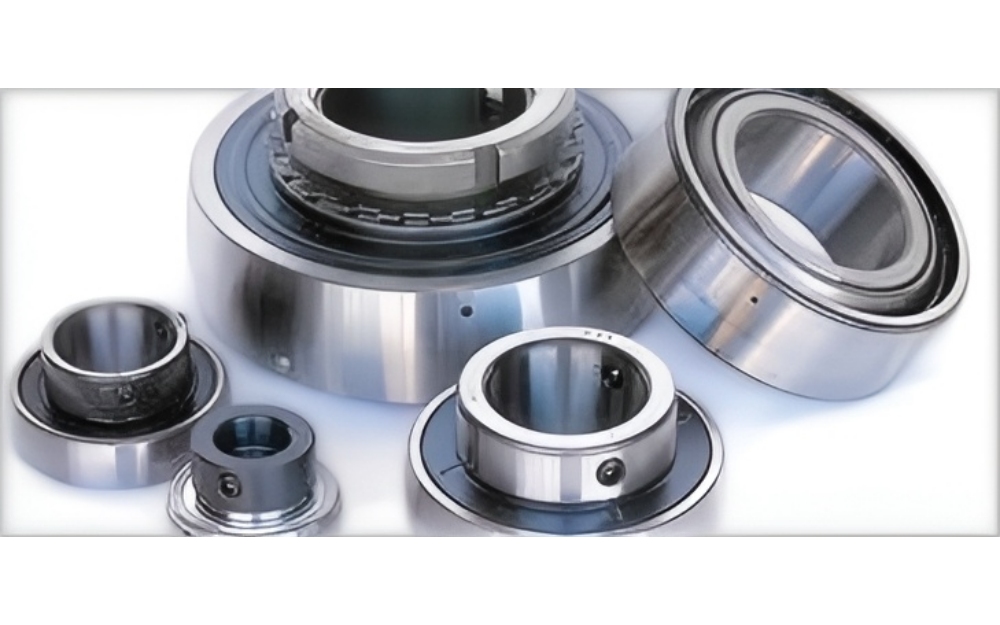

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025