How "Bearing Master" can carry the whole show and make your equipment say goodbye to "emo"!

Are you frustrated by the "stuttering" in your life?

Imagine this scenario:

You're at home on the weekend, making a healthy drink with your juicer. Suddenly, "squeak!" the machine makes a screeching noise, and then... it jams! Your perfect weekend instantly becomes "emo."

On your way to work, the subway suddenly stops in a tunnel, and an announcement comes over the loudspeaker: "Equipment malfunction, under repair." You can only sigh helplessly; your commute time instantly "collapses."

You're working late into the night, and your computer fan suddenly starts spinning wildly, making a huge noise, as if protesting its "overwork." Your train of thought also "freezes."

These moments of "stalling" and "disruption" in life, don't they make you feel particularly irritable, even emo? We strive for a smooth, efficient, and barrier-free life experience, but reality often falls short of our expectations.

This deep-seated pain point of "stalling" and "disruption" is an even more fatal threat in industrial production. When a piece of equipment malfunctions at a critical moment, it can range from impacting production efficiency to halting the entire production line, resulting in astronomical losses. The core component supporting the smooth operation of this equipment is often an inconspicuous yet crucial element—the bearing.

We will take you on an unprecedented and engaging journey to explore this "unsung hero" of industry—the bearing. You will not only learn how it maintains its smooth, "lying flat" operation even in extreme environments, becoming the true "core carry" of the equipment, but you will also discover how these delicate little parts ensure our modern lives are "smooth" and not "emo"! Get ready, an exploration of the secrets of industrial "smoothness" is about to begin!

From "friction deterrent" to "smooth ceiling"—the evolution of bearings.

From "Friction-Driven Deterrence" to "Smooth Ceiling"—The Evolution of Bearings

Before the invention of bearings, the earliest mechanical movements were fraught with friction and wear. Imagine two rough stones grinding against each other; the squeaking sound and rapid wear are a perfect illustration of the sluggishness of life without bearings.The Magic of Rolling: Humanity's Earliest "Friction-Reducing Tool"

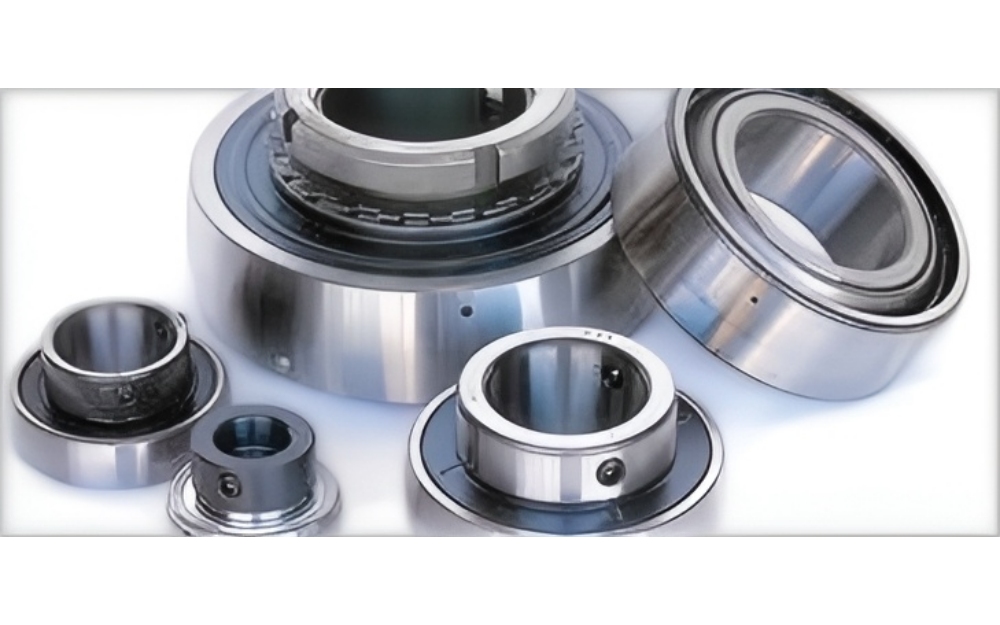

The core idea of bearings is simple: transform sliding friction into rolling friction. Two objects sliding against each other experience immense friction; however, adding a rolling element (like a log) greatly reduces this friction. Ancient Egyptians, when moving massive stones, had already learned to place logs underneath them to roll. This was the earliest "prototype" of bearings. Modern bearings have taken this idea to its extreme. Inside a precision bearing, balls or rollers roll between the inner and outer rings with an extremely low coefficient of friction, perfectly achieving a "smooth ceiling" operating state. This is like giving high-speed equipment a pair of "ice skates," making everything effortless.

The "Involution" of Materials and Manufacturing Processes: The Pursuit of Ultimate Wear Resistance and Stability To cope with diverse operating conditions, the materials and manufacturing processes for bearings are constantly undergoing a process of "involution."

High-carbon chromium bearing steel: This is the most common and readily available material, possessing extremely high hardness and wear resistance.

Stainless steel bearings: Facing humid and corrosive environments, stainless steel bearings act like special forces soldiers in waterproof suits, ensuring their resilience even in harsh conditions.

Ceramic bearings: If ordinary bearings are "tough guys," then ceramic bearings are "supercars." Lightweight, extremely hard, heat-resistant, and corrosion-resistant, they excel under extreme conditions such as high speed, high precision, and no lubrication, making them "high-precision players" in aerospace, Formula 1 racing, and other fields. The manufacturing precision of these bearings reaches an astonishing micron level; the diameter deviation of each ball may be only a few microns, dozens of times finer than a human hair. It is this extreme pursuit of detail that creates the smooth, "lying flat" operation of the bearing.

You may never have realized the existence of bearings, but they are ubiquitous, silently supporting the operation of our modern civilization.

"Wind Power Generation Experts": Ensuring a Continuous Flow of Clean Energy. Huge wind turbine blades, each tens of meters long, slowly rotate in the air. The core that supports their immense weight and withstands the impact of fierce winds is the giant wind turbine bearing. These bearings must be extremely robust and durable, ensuring the blades rotate smoothly in sub-zero temperatures and decades of continuous harsh environments, converting wind energy into electricity. They are true "invisible heroes," providing us with clean, green energy."Dancers on High-Speed Rails": The Stabilizing Force Behind a Flying Life. China's high-speed rail is renowned for its lightning speed and impeccable stability. Can you imagine a train carriage remaining perfectly stable at 350 km/h? The high-speed rail bearings are a key factor in this. These bearings must withstand enormous impacts, high-speed rotation, and severe vibrations, while maintaining extremely high precision and safety. They are like the "legs and joints" of a high-speed train, ensuring a smooth and seamless journey every time, making your "poetry and distant places" no longer a distant dream.

"The Pulse of the Smart Factory": The "Joints" of Industry 4.0 In a smart factory, robotic arms precisely grasp objects, conveyor belts operate at high speeds, and automated equipment works in tandem. These seemingly complex movements all rely on the support of countless industrial robot bearings and precision machine tool bearings. They must not only ensure the precision and speed of movement but also withstand long periods of continuous work and various complex loads. The reliability of bearings directly determines the efficiency and stability of a smart factory and is the cornerstone of achieving "Industry 4.0."

"The Unsung Heroes Around You": From Washing Machines to Hard Drives, Ubiquitous Beyond grand industrial scenarios, bearings also permeate your daily life. Your washing machine drum rotates smoothly thanks to its internal bearings; your car wheels spin at high speeds thanks to wheel bearings; even the hard drives in your computer and the power tools in your hand have miniature bearings working silently to ensure their smoothness and durability. They are true "unsung heroes," making your life free from "lag" and full of "smoothness."

When a Bearing "Goes Emo"—How to "Resurrect" It?

Even the strongest bearings have their "emo" moments. Excessive wear, insufficient lubrication, and contamination can all lead to decreased bearing performance and even failure. However, modern technology can effectively prevent these "emo" moments.Intelligent Monitoring: The Bearing's "Personal Health Consultant" Imagine your bearings could "talk"! Vibration sensors, temperature sensors, and oil analysis systems installed on equipment can monitor the bearing's "health status" in real time. These sensors act like the bearing's "personal health consultant," detecting subtle "groans"—abnormal vibrations, temperature increases, or deteriorated lubricating oil. Combined with AI and big data analytics, these systems can predict the bearing's remaining lifespan, reminding you to perform maintenance before potential failures occur. This is similar to your phone having a "battery warning" function, allowing you to charge in advance and avoid sudden shutdowns. This predictive maintenance (PdM) significantly extends bearing life and avoids unnecessary downtime losses.

Advanced Lubrication Technology: The Bearing's "Energy Supply Station" Lubrication is the bearing's "lifeline." Traditional greases or oils can fail under extreme temperatures or high speeds. Now, technologies such as synthetic lubricants, solid lubricants, and even magnetic levitation bearings are providing bearings with more durable and efficient "energy replenishment." For example, in certain cleanroom or vacuum environments, traditional lubricants can cause contamination. In such cases, using self-lubricating materials or magnetic levitation technology allows bearings to operate in a near-zero-friction state.

Rediscover the "Bearings" Around Us:

The next time you see a machine running smoothly, think about the bearings that silently support it and appreciate the convenience brought by technology!

Focus on Industrial Intelligent Upgrading: Learn more about technologies such as intelligent monitoring and predictive maintenance, which will be key to the future development of industry.

Support Technological Innovation: Every small technological advancement can bring about huge changes to our lives!

Let's give a thumbs up to these unsung heroes and enjoy the smooth life they bring!

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025