About Us

The Hidden Technology of Bearings

Views : 171

Update time : 2025-11-03 13:06:00

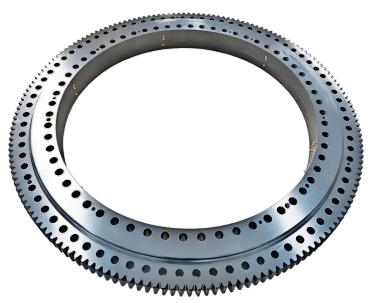

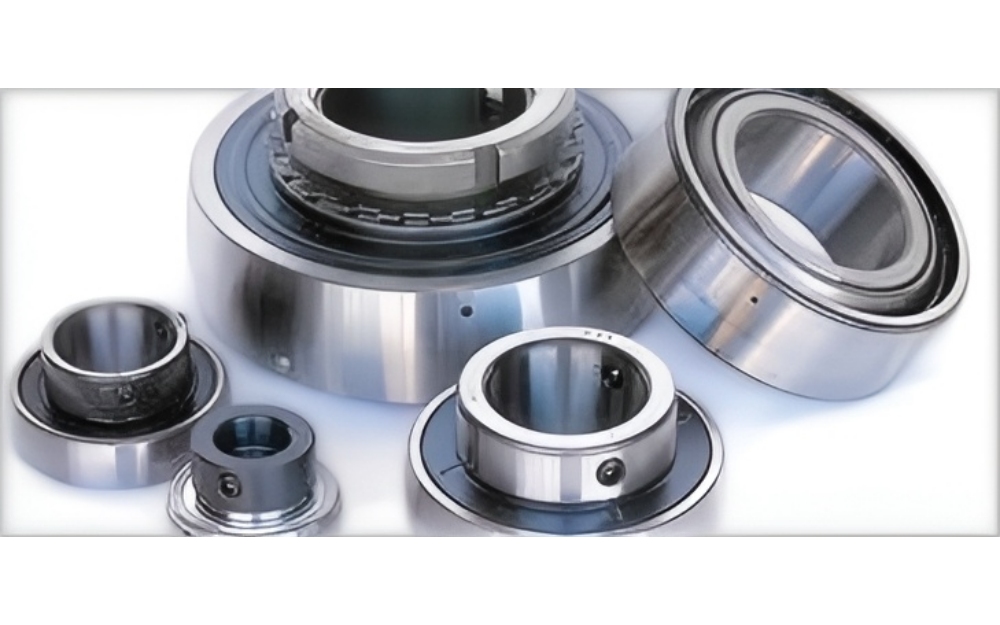

Bearings are ubiquitous and used in an exceptionally wide range of applications.

Today, we'll unveil some of the bearing technologies you may have never heard of—the cutting-edge technologies in bearings.

I. Bearings That "Self-Repair"

Traditional bearings wear down during operation due to friction. Over time, microcracks on the surface expand into damage, leading to noise, vibration, and even failure. The principle behind "self-repairing bearings" is the addition of microcapsules to the lubricating grease or surface material. When cracks appear on the surface, these microcapsules rupture, releasing a repair agent that reacts chemically with metal ions to quickly fill the cracks.This technology originated in the aero-engine field and is now being gradually extended to industries such as wind power and heavy-duty machinery.

II. Bearings That "Think"

As mentioned earlier, intelligent bearings can monitor parameters such as temperature, vibration, speed, and lubrication status in real time and transmit this data to the control system.For example, Schaeffler's intelligent bearing unit can use AI algorithms to predict potential wear trends in advance, enabling "predictive maintenance."

In large factories, wind farms, or high-precision equipment, predictive maintenance can save significant downtime costs and make production safer and more efficient.

Ⅲ, Bearings That Can Rotate Without Oil

When bearings are mentioned, many people's first reaction is "lubrication is required."

However, in vacuum, high-temperature, or radiation environments, oil simply cannot withstand the strain.

So, is it possible for bearings to rotate without oil? The answer is—yes.

"Solid-lubricated bearings" use special materials on the friction surfaces, such as graphite, molybdenum disulfide, or boron nitride. These materials can form an extremely thin "slip film" on the metal surface, reducing friction and extending lifespan.

NASA has developed such bearings for use in spacecraft. They can operate stably in temperatures ranging from -200°C to 500°C and require almost no maintenance.

Ⅳ, "Ceramic Bearings" Stronger Than Steel

Don't think of ceramics only as a material for making dishes.

In the field of high-end bearings, ceramics have long been the king of performance.

The balls of ceramic bearings are made of silicon nitride or zirconium oxide, which are high in hardness, low in density, resistant to high temperatures, and corrosion-resistant.

Compared to traditional steel, it is lighter, has less friction, and a longer lifespan.

Ceramic bearings have become standard equipment in high-speed electric spindles, electric racing cars, and precision medical equipment.

Most remarkably, they are unaffected by magnetic fields and remain stable even in strong magnetic environments such as MRI machines.

In summary: Tiny bearings, a vast world.

From wind turbines to electric vehicles, from automated factories to space exploration, they silently turn, supporting the operation of human civilization. Every turn of theirs represents technological progress.

相关新闻

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

Jan 30,2026

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Jan 05,2026

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Dec 26,2025

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Dec 19,2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025