Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Not Just a Structural Difference, but a Decision That Affects Performance.

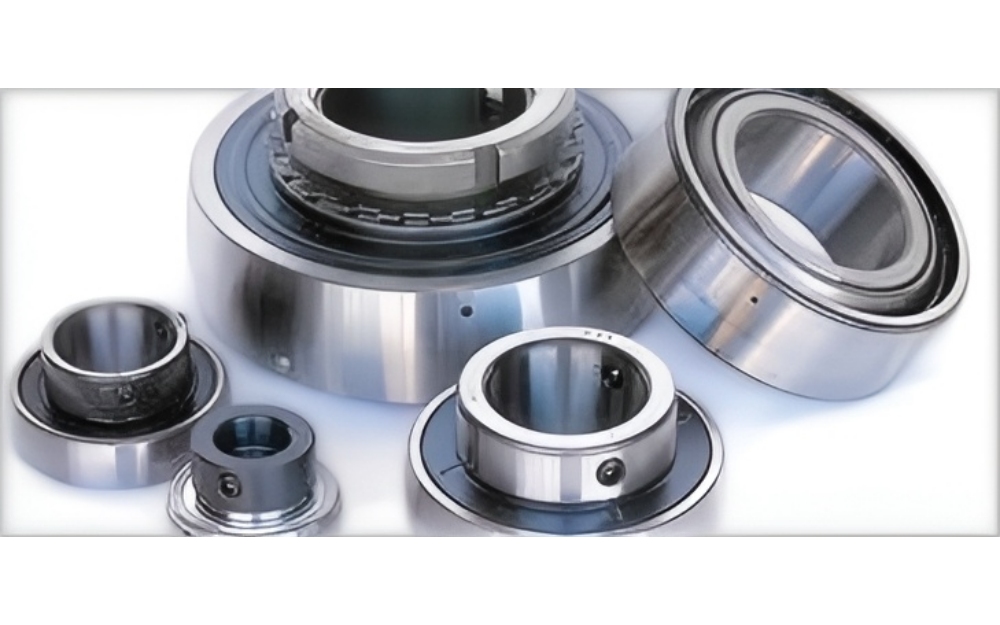

In the world of bearings, few comparisons appear more frequently than deep groove ball bearings and angular contact ball bearings. They look similar at first glance. Both use steel balls, both rely on raceways, and both are widely used across industries—from electric motors to machine tools.

Yet in real applications, choosing the wrong one can lead to excessive vibration, shortened service life, unexpected heat, or even catastrophic failure.

So what really separates these two bearing types?

And more importantly, when should you choose one over the other?Let’s break it down—not from a catalog perspective, but from how these bearings actually behave in machines.

1. The Core Structural Difference (And Why It Matters)

At a basic level, the difference lies in how the load travels through the bearing.

Deep Groove Ball Bearings

In a deep groove ball bearing, the raceways on the inner and outer rings are symmetrical and deeply curved. The balls sit comfortably between them, and the load path is nearly vertical when viewed in cross-section.

This design allows the bearing to:

-

Carry radial loads very efficiently

-

Handle moderate axial loads in both directions

-

Operate smoothly at high speeds

The key word here is balance. Deep groove ball bearings are designed to work well under many conditions, even if none of them are extreme.

Angular Contact Ball Bearings

Angular contact ball bearings, on the other hand, deliberately tilt the load path. The raceways are offset, creating a contact angle—typically 15°, 25°, or 40°.

Because of this angle:

-

Radial and axial loads are transmitted simultaneously

-

Axial load capacity is significantly higher—but only in one direction

-

Stiffness increases, especially under axial force

In short, angular contact bearings are optimized for directional load control, not general-purpose use.

2. Load Capacity: “Can Carry” vs. “Designed to Carry”

This is where misunderstandings often occur.

Deep Groove Ball Bearings: Versatile but Limited

Yes, deep groove ball bearings can carry axial loads. But that doesn’t mean they are designed to handle large or continuous axial forces.

They perform best when:

-

Radial load dominates

-

Axial load is light or intermittent

-

Load direction is unpredictable

For example, in an electric motor, the shaft may experience small axial forces due to magnetic pull or thermal expansion. A deep groove ball bearing handles this easily and without complaint.

Angular Contact Ball Bearings: Purpose-Built for Axial Load

Angular contact bearings excel where axial load is significant and consistent.

Common scenarios include:

-

Machine tool spindles

-

Ball screw support systems

-

Pumps and compressors with thrust forces

However, because axial load can only be handled in one direction, these bearings are often installed:

-

In pairs (back-to-back or face-to-face)

-

Or in sets with precise preload

This is not optional—it’s fundamental to their correct operation.

3. Speed Capability: Not All High-Speed Bearings Behave the Same

Both bearing types are capable of high-speed operation, but the conditions differ.

Deep Groove Ball Bearings

These bearings are often the first choice for high-speed applications because:

-

They have lower friction

-

They require minimal preload

-

Heat generation is relatively low

That’s why they dominate in:

-

Fans and blowers

-

Small motors

-

Household appliances

-

Light industrial equipment

They are forgiving. Slight misalignment, minor mounting errors, or lubrication variations usually won't cause immediate problems.

Angular Contact Ball Bearings

Angular contact bearings can also run at high speeds, but only when:

-

Preload is carefully controlled

-

Lubrication is optimized

-

Heat dissipation is considered

In machine tools, for example, high-speed spindle bearings are angular contact types—but they operate in tightly controlled environments. A small setup error can lead to rapid temperature rise and loss of accuracy.

So while both can spin fast, deep groove bearings tolerate speed, while angular contact bearings demand precision.

4. Stiffness and Accuracy: Where Angular Contact Bearings Shine

If your application involves precision, this is where the choice becomes clear.

Deep Groove Ball Bearings

They provide adequate stiffness for:

-

Standard rotating equipment

-

Non-precision positioning

-

Applications where vibration control is not critical

However, under axial load, internal clearance changes can lead to:

-

Shaft movement

-

Reduced positional accuracy

-

Inconsistent performance

Angular Contact Ball Bearings

Thanks to their contact angle and preload capability, angular contact bearings offer:

-

Higher axial stiffness

-

Better control of shaft displacement

-

Improved vibration behavior

This is why CNC machines, grinding spindles, and precision motion systems almost always rely on angular contact bearings.

If accuracy matters, deep groove bearings are usually a compromise. Angular contact bearings are a solution.

5. Installation and Maintenance: Simple vs. Sensitive

Deep Groove Ball Bearings: Install and Forget

One of the biggest advantages of deep groove ball bearings is ease of use.

They typically:

-

Require no preload adjustment

-

Allow for simple mounting

-

Tolerate small alignment errors

This makes them ideal for mass production and general machinery.

Angular Contact Ball Bearings: Precision Required

Angular contact bearings are far less forgiving.

Correct installation involves:

-

Matching bearing orientation

-

Setting the correct preload

-

Controlling shaft and housing tolerances

Improper installation can negate all their advantages—and sometimes make performance worse than a deep groove bearing.

6. Typical Applications: Real-World Usage

Deep Groove Ball Bearings Are Commonly Used In:

-

Electric motors

-

Gearboxes with light axial load

-

Conveyors

-

Fans and pumps (low thrust)

-

Agricultural and general industrial equipment

Angular Contact Ball Bearings Are Commonly Used In:

-

Machine tool spindles

-

Ball screw supports

-

High-speed pumps

-

Precision reducers

-

Automotive transmissions (specific positions)

The overlap is smaller than it appears. In most machines, one type clearly makes more sense than the other.

7. How to Choose: A Practical Decision Guide

Ask yourself these questions:

-

Is axial load significant and continuous?

→ Choose angular contact ball bearings. -

Is load direction predictable and controlled?

→ Angular contact bearings perform better. -

Is simplicity, cost, and robustness more important than precision?

→ Deep groove ball bearings are the safer choice. -

Is this a high-precision or positioning-critical application?

→ Angular contact bearings are worth the extra effort.

If you’re still unsure, defaulting to a deep groove ball bearing is often acceptable—unless axial load or accuracy requirements prove otherwise.

Final Thoughts

The difference between deep groove ball bearings and angular contact ball bearings isn’t about which one is “better.” It’s about what the machine actually needs.

Deep groove ball bearings are the quiet workhorses of industry—reliable, flexible, and easy to use.

Angular contact ball bearings are specialists—demanding more care, but delivering superior performance where it counts.

Choose based on load direction, precision requirements, and installation capability—not just what looks similar on paper.

When the bearing matches the application, everything else runs smoother.

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025