How Bearings Quietly Eliminate Friction?

How Bearings Quietly Eliminate Friction?

In our daily lives, from the roar of a car engine to the smooth operation of a washing machine, almost all mechanical motion is related to friction. It is this friction that relentlessly consumes precious energy, causing rapid wear of parts and dangerous heat buildup. Have you ever wondered what force allows for continuous, smooth, and efficient movement in modern machinery operating at high speeds and under heavy pressure?

This article will unveil the mystery of bearings, taking you deep into the world of machinery and showing you how these unsung heroes use ingenious engineering principles to transform destructive sliding friction into almost negligible rolling friction.

By reading this article, you will understand the three core secrets of how bearings "quietly eliminate" friction in terms of structure, materials, and lubrication, mastering the key technological foundation for the efficient operation of modern machinery.

The Three Major "Hidden Dangers" of Friction: Why Must It Be Eliminated?

Before understanding how bearings work, we must first clarify the dangers of friction and why eliminating it is crucial for engineering design.Energy Loss and Efficiency Killer

Friction is one of the most significant forms of energy loss. When two surfaces slide against each other, a continuous force is needed to overcome this resistance, converting the energy originally intended to drive the machinery into useless heat. In large industrial equipment, even small amounts of friction can accumulate and cause significant energy waste, directly impacting production costs and efficiency. The goal of bearings is to minimize this unproductive energy conversion.Wear and Lifespan Terminator

Friction means contact and wear. Prolonged sliding friction causes metal surface materials to peel and deform, leading to changes in part dimensions and geometry. This continuous damage eventually results in decreased mechanical precision, increased noise, and ultimately, complete equipment failure. Bearings, by isolating or changing the contact method, become key guardians of mechanical lifespan.Heat Accumulation and Operational Risks

The heat generated by friction accumulates rapidly under high-speed or heavy-load conditions. Excessive temperatures not only reduce the performance of lubricants but can also cause thermal expansion of metal parts, loss of clearance, and ultimately catastrophic failures such as **seizing**. Low-friction bearing design is fundamental to ensuring the long-term operation of machinery within safe temperature ranges.The Core Secret to Bearings' "Silent Elimination" of Friction

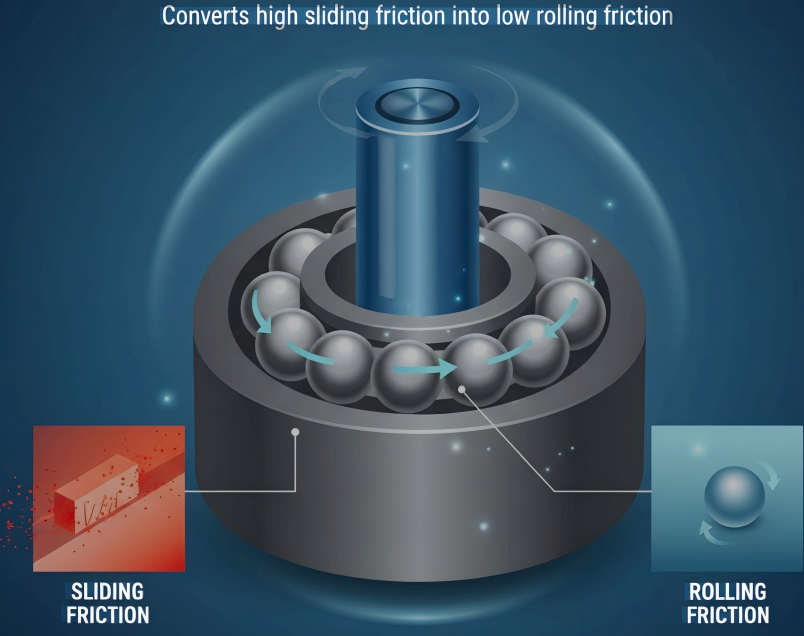

Bearings are called "friction termins" because they break down an engineering problem into several controllable steps.The Revolution from Sliding to Rolling

-1)This is the core principle of bearings: replacing sliding friction with rolling friction.-2)Sliding friction: Microscopic protrusions between contact surfaces lock and shear each other, resulting in high resistance.

-3)Rolling friction: When rolling elements (balls or rollers) roll on a track, the contact area is extremely small, and resistance mainly comes from the elastic deformation and minute slippage of the material.

-4)Physics research shows that under the same load and material conditions, the coefficient of rolling friction can be an order of magnitude or even more smaller than the coefficient of sliding friction. Bearings successfully achieve this revolution in friction type conversion through their internal balls or rollers.

-5)Precision Structure and Key Components

The quiet and friction-reducing effect of bearings relies on the perfect cooperation of four key internal components.-6)Inner Ring and Outer Ring:

Provide raceways to ensure smooth operation of the rolling elements. Their materials (typically high-carbon chromium bearing steel) and surface finish are crucial; even minute defects can lead to friction and noise.

-7)Rolling Elements: Balls or rollers. They are the core of achieving "rolling" and must possess extremely high hardness, wear resistance, and precise geometry.

-8)Cage/Retainer: Responsible for evenly separating the rolling elements, preventing them from contacting and rubbing against each other, and guiding them back in the non-load-bearing area. This is a key design feature ensuring low-noise, long-life bearing operation.

-9)Lubricant: The "Invisible Shield" of Friction

Even in rolling, microscopic contact still exists between metal surfaces. Excellent bearing design relies heavily on lubricants (oil or grease).The lubricant forms an extremely thin oil film between the rolling elements and raceways, acting like an **"invisible shield"**, completely or partially isolating the metal surfaces. This not only further reduces friction (fluid friction) but also absorbs and carries away heat, prevents rust, and greatly extends the bearing's lifespan and operating efficiency.

-10)Modern Bearing Family: Targeted Friction Reduction

Bearings are not a single type; engineers have designed various specialized "friction reduction experts" based on different application scenarios and load characteristics.-11)Deep Groove Ball Bearing:

General-Purpose Friction Reduction Expert

This is the most common type of bearing, named for its deep groove raceways on both inner and outer rings.Features: Simple structure, suitable for high-speed operation, capable of simultaneously bearing radial loads (perpendicular to the axis) and a certain amount of axial load (parallel to the axis).

-12)Friction Reduction Advantages:

Small contact point, extremely low frictional torque, a model of "quietly eliminating friction," widely used in motors, household appliances, and light machinery.

-13)Roller Bearings:

Handling Heavy Loads and Impacts

The rolling elements of roller bearings are rollers (such as cylindrical, tapered, or spherical), not balls.

Features: Longer contact line between the rolling elements and raceways, resulting in a much higher load-bearing capacity than ball bearings.Friction Reduction Advantages: Despite their complex structure, bearings distribute heavy load pressure by increasing the effective contact area, avoiding sliding and wear caused by localized high pressure. They are suitable for high-load, high-impact applications such as speed reducers, heavy machine tools, and engineering vehicles.

Bearings are the silent revolutionaries of modern machinery.

Bearings successfully and efficiently eliminate the enormous harm caused by friction within a very small space by converting sliding friction into rolling friction, combined with precise geometry and a reliable lubrication system. These inconspicuous little components ensure that everything around us—from wind turbines to medical equipment—operates sustainably, efficiently, and smoothly.

Call to Action:

The next time you see a bicycle wheel turning smoothly or hear the steady hum of factory equipment, please show more respect. Behind this is a great victory for bearing engineering. Consider how disruptive changes further friction reduction technologies in bearings will bring to your areas of interest (such as electric vehicles, aerospace).

FAQ: Frequently Asked Questions and Answers Why is rolling friction much less than sliding friction?

Sliding friction occurs between two macroscopic planes, where microscopic protrusions on the contact surfaces interact, requiring energy to overcome shear and adhesion. Rolling friction, on the other hand, involves a very small contact area (theoretically point or line contact), with resistance primarily arising from the minute elastic deformation of the rolling elements and raceways, as well as the small displacements and internal forces of the rolling elements on the raceways.

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025