If your robot has started to make weird noises, hesitates in its movements, or just generally “isn't what it used to be,"don't call a technician just yet—sit down, take a deep breath, and ask yourself: Is it going through a midlife crisis?

More specifically: Have you checked its bearings lately?

Robots, just like people, can reach a point where their smooth performance hits a snag.

And when they do, it's often not existential dread—it's mechanical wear and tear. Bearings, though tiny and often overlooked, are critical components in a robot's anatomy.

When they start to fail, your robot might show symptoms that are eerily familiar to someone buying a sports car at 50.

Let's get under the hood and explore why bearings are so vital, how their deterioration mimics a robotic identity crisis, and what you can do to get your machine back to peak performance.

The Soul of Smooth Movement: What Bearings Actually Do

In robotics, bearings are like the joints in your own body.

They allow moving parts—arms, wrists, wheels, grippers—to rotate or shift with minimal friction.

Whether it's a six-axis industrial robot assembling car parts or a home robot vacuum dodging your furniture, bearings are what let them move precisely, reliably, and without awkward hiccups.

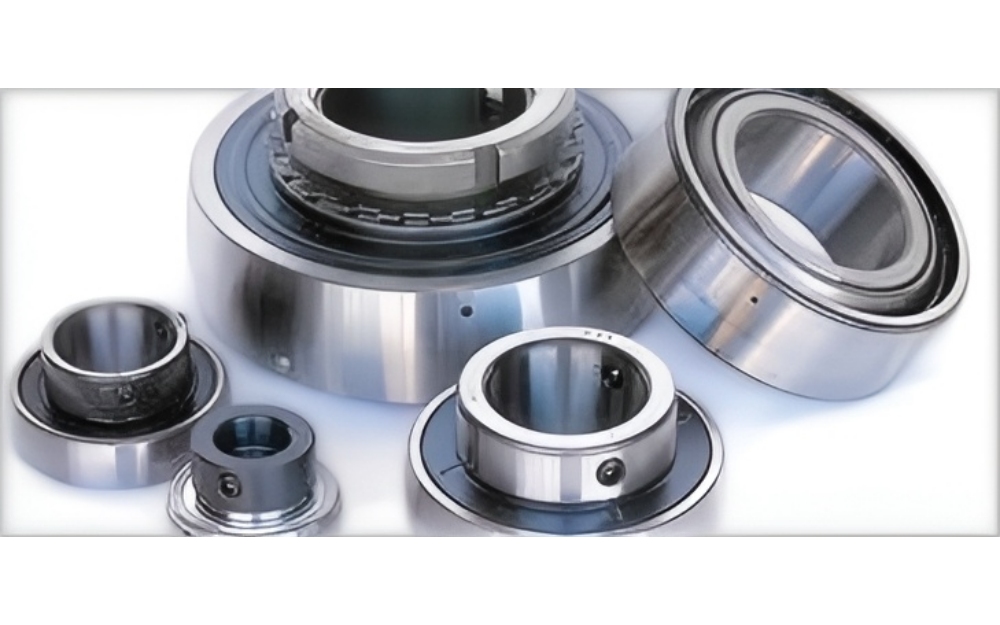

There are different types of bearings used in robotics:

Ball Bearings: Common in lightweight applications. They offer smooth rotation at high speeds.·

Roller Bearings: Great for handling heavy radial loads.

Crossed Roller Bearings: Popular in robotic arms for their high rigidity and accuracy.

Thrust Bearings: Used for axial loads, such as in vertically moving robot components.

Miniature Bearings: Ideal for compact robots and wearables.

These components operate under constant stress.

And just like human knees after a decade of jogging, they start to wear down.

Symptoms of a Robot in Crisis

Imagine this: your once-silent robotic arm now whines like a blender full of marbles.

Its once-precise pick-and-place movements are sluggish.

The gripper misses its target. Your robot is still technically functioning—but clearly, something's off.

Here's how bearing issues manifest:

Increased Noise – Failing bearings often emit grinding, whining, or humming sounds as internal surfaces degrade.

Vibration and Jerky Motion – Uneven rolling elements or damaged races cause misalignment and erratic movements.

Overheating – Friction from worn bearings can generate excess heat, causing component damage.

Loss of Precision – Slop or play in robotic joints due to bearing wear leads to poor accuracy.

Sudden Stops or Stalls – Bearings nearing catastrophic failure can seize, causing motors to overload or stop entirely.

If your robot is showing any of these signs, it's not rebelling—it's begging for maintenance.

How to Fix Your Robot's “Midlife” Crisis

Unlike humans, robots don't need therapy—they need a torque wrench and a fresh set of bearings. Here's how to approach the situation:

1. Inspect Regularly

Set up a maintenance schedule that includes routine inspection of key bearing locations.

Use vibration analysis tools or thermographic cameras to detect early signs of failure.

2. Choose the Right Bearing for the Job

Don't use a ball bearing where a crossed roller is needed.

Work with your bearing supplier to match specs to your robot's loads, speeds, and environment.

3. Mind the Lubrication

Follow manufacturer recommendations for lubricant type and re-lubrication intervals.

Consider sealed bearings for environments prone to contamination.

4. Replace in Pairs (or All at Once)

If one bearing is failing, others in the same load path may not be far behind.

It's often more cost-effective to replace them together than risk unexpected downtime.

5. Upgrade When Necessary

In some cases, upgraded bearings (e.g., ceramic hybrids, precision-grade units, or shielded designs) offer longer life and better performance.

The Comeback: When Your Robot Finds Itself Again

Once you've replaced the bearings and done a full systems check, the transformation is dramatic.

The whirring disappears.

Movements are fluid again.

Precision returns. Your robot is, quite literally, back in its groove.

And just like that, the “midlife crisis” is over.

No need for self-help books or motivational podcasts—just well-maintained hardware.

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025