About Us

The Bearing Revolution: When Traditional Machinery Meets the Smart Era

Views : 166

Update time : 2025-12-01 09:41:54

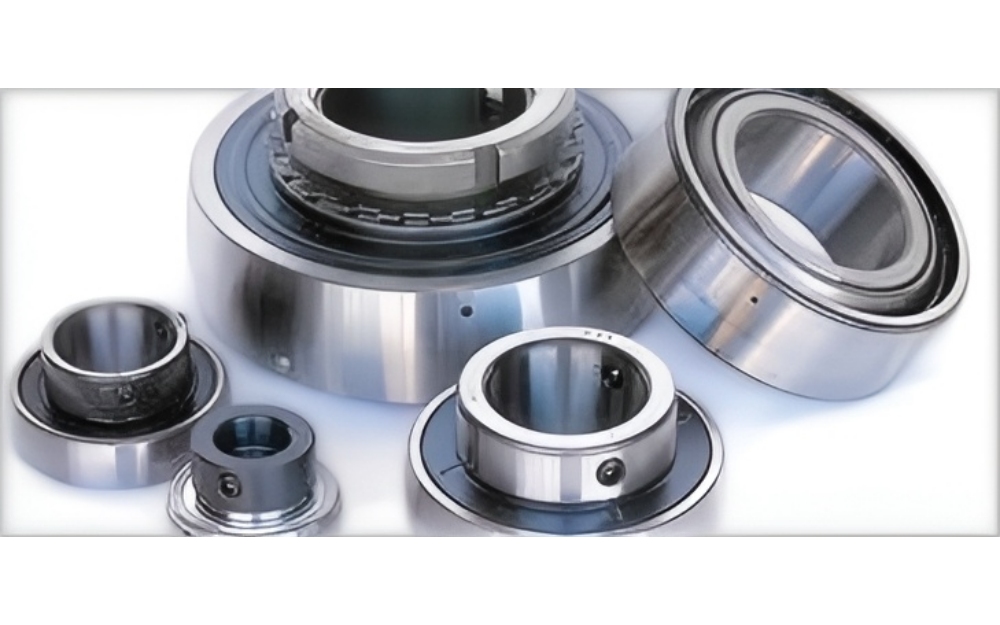

In most people's minds, a bearing might just be an inconspicuous metal ring in a mechanical device. But this seemingly simple component is undergoing a silent technological revolution. From wind turbines to intelligent robots, from high-speed trains to medical devices, the new generation of intelligent bearings is redefining the possibilities of mechanical transmission.

Three Breakthroughs of Intelligent Bearings

1) Self-Sensing Capability: Modern bearings have built-in sensors that can monitor data such as temperature, vibration, and load in real time. Like equipping machinery with a "health bracelet," it can provide early warnings of malfunctions and enable predictive maintenance.2) Self-Lubricating Technology: Nanomaterial coatings allow bearings to operate for their entire lifespan without maintenance. Imagine a wind turbine operating continuously for years at a height of hundreds of meters without human intervention; this is thanks to self-lubricating bearings.

3) Energy Harvesting Function: Piezoelectric bearings can convert mechanical vibrations into electrical energy to power sensors. This self-sufficient design makes bearings more competitive in the Internet of Things era.

Future Trends: Cross-Industry Integration of Bearings

1) Medical Field: Precision bearings used in surgical robots achieve micron-level accuracy, finer than a human hair. These "thinking" bearings can automatically adjust their rigidity according to surgical needs, ensuring operational precision.2) New Energy Vehicles: Low-friction bearings help electric vehicles extend their driving range. Some innovative companies have even developed drive bearings with integrated motor functions, reducing the size of the transmission system by 40%.

3) Space Exploration: Space bearings can operate stably in extreme temperatures and vacuum environments, providing reliable support for lunar base construction and deep space exploration.

Practical Advice for Engineers

1) New Selection Approach: Don't just look at load parameters; pay more attention to the bearing's intelligent functions and data interfaces.2) Maintenance Transformation: From routine inspections to data-driven predictive maintenance.

3) Skills Upgrade: Learning data analysis skills is essential to fully realizing the potential of intelligent bearings.

This seemingly traditional industry is actually full of innovative vitality.

The next time you hear the sound of machinery running, consider this—it might not just be the friction of metal, but rather intelligent bearings "speaking."

相关新闻

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

Jan 30,2026

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Jan 05,2026

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Dec 26,2025

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Dec 19,2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025