About Us

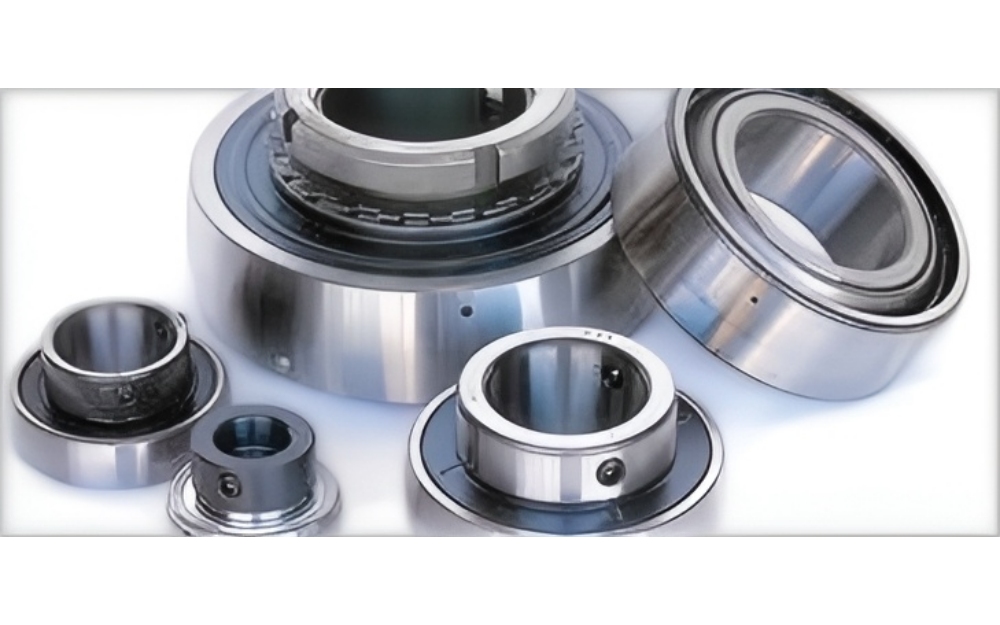

The "Transformers" of the Bearing Industry: 3D Printing Enables "Personalized Customization" of Bearings

Views : 154

Update time : 2025-11-17 21:16:10

Hello everyone! Imagine your equipment, whether it's a wind turbine behemoth or a high-speed motor.

Its core component—bearings—used to be mass-produced on assembly lines, much like a standardized lunch in a factory canteen. They were hardworking and reliable, but always felt a bit lacking in individuality.

But now, times have changed! With the rise of additive manufacturing (commonly known as 3D printing), this "new force," bearings can finally shout the classic line to the world: "I want to be different!"

1. Say Goodbye to "Assembly Line Fast Food," Embrace "Customized Feasts"

Traditional bearing manufacturing is like making shoes of the same size for everyone on Earth—simple, crude, and as long as it works. But what about 3D printing? It's like a magical tailor, or rather, a "personalized customization studio" specifically designed for bearing components.

Cages: No Longer Just Boring "Nanny"

Bearing cages, those unsung little parts that silently "manage" the rolling elements, used to have very standard shapes. But now, we can use 3D printing technology to quickly manufacture all sorts of incredibly complex geometries.

Imagine if the cage is the bearing's "personal trainer." The old trainer would only say, "Run!" Now, the trainer can have customized ventilation channels, optimized lubrication grooves, and even integrate a bunch of miniature supports. What does this mean? It means we can quickly test a wildly imaginative cage design. If it fails, no problem, Ctrl+Z, reprint! This speed would make traditional mold manufacturing cry "involution!"

2. Integrated Sensors? Call Me a "Bearing with a Brain"

In the Industry 4.0 era, it's not enough for a bearing to just rotate; it must be able to "talk," telling its owner, "I'm getting a little hot," or "I think I'm a little tired."

Previously, attaching "ears" (sensors) to bearings often required designing complex brackets, like building a temporary "signal tower" next to the bearing. Now, 3D printing can directly print the necessary sensor mounting structure on the cage or in specific locations on the bearing housing, creating a single, integrated unit.

This is like: previously you had to carry your phone case and power bank separately; now, 3D printing directly integrates a phone case with a solar charging panel. It gives bearings a true "brain circuit," transforming them from silent, mechanical laborers into proactive "intelligent employees."

3. A Hybrid Party of Materials

The world of bearing materials has always been rigorous, but 3D printing has brought entirely new possibilities. Metal 3D printing (such as SLM and EBM) allows us to explore new alloys or composite materials that are difficult to handle with traditional casting or forging processes.

This is like breaking down the "barriers" in the materials science world, giving various hybrid alloys the opportunity to take center stage in bearings. Perhaps in the future, we will see a bearing component as light as a feather and as hard as a diamond, capable of effortlessly "dancing" at 500°C. Its creation stems from the layer-by-layer magic of 3D printing.

4. Who says bearings can't be "personalized"?

In extreme applications (such as aerospace and medical equipment), the demand is often small-batch, highly customized. This is where the advantages of 3D printing truly shine.

For example, do you have a device requiring extremely high speeds but with extremely unique dimensions, and you can't find a suitable cage on the market? No problem! Send us your CAD file, and we'll "bake" one for you! This ability for customized production frees bearings from the constraints of standard parts, truly achieving "a thousand machines, a thousand faces."

In summary, 3D printing brings to bearings not just a simple speed increase, but a liberation of thought:

Liberating design: From "what can be manufactured" to "what can be imagined."

Liberating maintenance: From "replacing when it breaks" to "early warning," because sensor structures are easier to integrate.

Liberating Materials: The Infinite Possibilities of Transforming "Traditional Alloys" into "Future Alloys"

So, the next time you see a bearing spinning rapidly, remember, it might no longer be that dull, unassuming machine, but a "mechanical supermodel" enhanced by 3D printing, equipped with an intelligent brain, and possessing a super cage! The bearings of the future are definitely much cooler than you imagine!

相关新闻

What type of bearings are used in wind turbines?

What type of bearings are used in wind turbines?

Jan 30,2026

What type of bearings are used in wind turbines?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Jan 05,2026

The "20-year promise" of wind turbine bearings: How to combat sea winds at an altitude of 100 meters?

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Dec 26,2025

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Dec 19,2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025